About Screw Blower

BLG Permanent Magnet Variable Frequency Screw Blower is an advanced compressed air system designed for energy efficiency and precise control in industrial applications. This blower combines cutting-edge motor and drive technology with

robust screw compression, making it ideal for industries prioritizing energy savings, operational flexibility, and reliability. Its design addresses modern needs for sustainability and cost-effective performance in dynamic environments.

| Model |

BLG343A/BL343B |

| Outlet size |

DN350/DN450 |

| Airflow(m³/min) |

73-136/94-172 |

| Motor Power(KW) |

75-220/90-280 |

| Speed(Rpm) |

1800-3000 |

Specifications to Consider

1,Airflow capacity (m³/min or CFM)

2,Pressure range (bar or psi)

3,Motor power rating (kW) and efficiency class (e.g., IE5)

4,Noise levels (dB) and cooling method (air/water-cooled).

Working Principle

A rotary screw compressor using twin meshing screws for positive displacement air compression.Provides smooth, pulsation-free airflow with lower vibration/noise compared to piston blowers.The working cycle of screw blower can be divided

into three processes: suction, compression and exhaust. The cycle process is as follows:

1. Suction process

Picture ① : The air enters the volume between the teeth of the rotor through the suction port. As the rotor rotates, the volume between the teeth continuously expands.

Picture ② : When the volume between the teeth reaches the maximum, the volume between the teeth is disconnected from the suction port and the suction process ends.

2. Compression process

Picture ③: during compressing

3. Exhaust process

Picture ④: After the inter-tooth volume is connected to the exhaust port, the exhaust process begins. During the rotation of the rotor, the volume between the teeth continuously decreases, sending the compressed air to the exhaust pipe. This process continues until the volume reaches designed data.

Applications

Wastewater Treatment: Variable aeration demands in biological processes.

Industrial Processes: Pneumatic conveying, fermentation, or manufacturing requiring stable airflow.

HVAC Systems: Efficient air handling in large facilities.

Company Brief

B-Tohin Machine (Jiangsu) Co., Ltd., a foreign-funded enterprise established in 1994,is located in the Industrial Park for Environmental Science and Technology ,Yixing ,China. B-Tohin is mainly engage in the production

and sales of roots blowers,rotary blowers,single-stage high-speed centrifugal blowers,multi-stage centrifugal blowers,air foil bearing centrifugal blowers,magnetic suspension centrifugal blowers,FRP fans,vacuum pump

sand water pumps,and in the sales of Japan ShinMaywa water pumps.The products are sold all over the country and exported to many countries and regions for application in environmental water treatment

building,materials and cement, chemical industry ,electric power,petroleum,steel,metallurgy,mining,printing and dyeing,grain transportation ,new energy ,new materials and other industries.Now the company has formed

an annual production and sales scale of more than 30000 sets of blowers and water pumps.

The company has passed the ISO9001 quality management system certification,ISO 1400 environmental management system certification ,ISO45001 occupational health and safety management system certification and

the “five-star”certification of national standard GB/T27922-2011 “Commodity After-sale Service Evaluation System” and it was named as “Specialized ,Refine, Characteristic and Innovative Enterprise of Jiangsu

Provinces “,also was recognized as the “Enterprise in Compliance with the Standard Conditions for Environmental Protection Equipment Manufacturing Industry in 2002 (Announcement No.28 of the Ministry of

Information Technology of the People’s Republic of China in 2001).

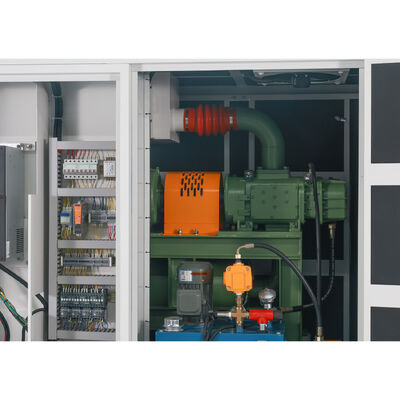

Main machine

FAQ

Q1. Are you manufacturer or trading company?

We are the professional machinery manufacturer.Now the company has formed an annual production and sales scale of more than 30000 sets of blowers and water pumps.

Q2: Where is your factory located? May I have a visit?

Warmly welcome! Our factory is located in the Industrial Park for Environmental Science and Technology , Yixing, China.

Q3:What's the information should I provide when inquiry?

A: Air capacity

B: Pressure

C: Application

D: Use environment(Temperature, atmospheric pressure)

E: Do you need motor?

Or other specials you give us will be more appreciated.

Q4: What is your warranty?

Our warranty is 12 months after received the machine.

Q5. How does your factory control product quality?

We have quality inspection department. Before sending out product, we check each product. If there is quality problem, we will produce new one.

Q6.What is the delivery time?

Product delivery time is generally within 45 days from receipt of deposit.

Q7.Does your machine with CE certificate?

Yes.We have CE certificate,we will offer it if you need.

Q8. Do you accept customization?

We accept customization and we have a professional technical team to provide you with the best solution.

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!  يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!