Screw Blower

Working Principle

1. Suction starts

2. Suction ends and compression begins

3. During compression

4. Compression ends and air discharge begins

Machine Specifications

| Force- lubrication |

Pressure Range |

100-200KPa |

Airflow Range |

3-200m³/min |

Power Range |

11-500kw |

| No. |

Model |

Diameter |

Exhaust Pressure

(KPa)

|

Airflow

(m³/min)

|

Motor Power

(Kw)

|

Main Body Speed

(rpm)

|

| 1 |

BLG115RA-Ⅱ |

DN150 |

100-150 |

3.0-6.8 |

11-22 |

3500-6000 |

| 2 |

BLG115RB-Ⅱ |

4.0-9.4 |

11-30 |

3500-6000 |

| 3 |

BLG170RA-Ⅱ |

11.2-23.1 |

30-75 |

2800-5000 |

| 4 |

BLG170RB-Ⅱ |

15.3-315 |

30-90 |

2800-5000 |

| 5 |

BLG210RA-Ⅱ |

DN250 |

100-150 |

22.6-45.8 |

45-110 |

2600-4800 |

| 6 |

BLG210RB-Ⅱ |

28.2-56.6 |

55-132 |

2600-4800 |

| 7 |

BLG300RB-Ⅱ |

DN300 |

100-150 |

55.3-98.9 |

110-250 |

2000-3300 |

| 8 |

BLG360RB-Ⅱ |

DN350 |

100-150 |

101.2-196.4 |

220-480 |

1800-3100 |

| 9 |

BLG170RA-Ⅲ |

DN150 |

160-200 |

10.5-21.1 |

45-75 |

3000-5000 |

| 10 |

BLG170RB-Ⅲ |

14.8-28.9 |

45-110 |

3000-5000 |

| 11 |

BLG210RA-Ⅲ |

DN250 |

160-200 |

20.5-42.1 |

75-132 |

2800-4800 |

| 12 |

BLG210RB-Ⅲ |

28.1-53.6 |

75-160 |

2800-4800 |

| 13 |

BLG300RB-Ⅲ |

DN300 |

160-200 |

52.1-95 |

160-315 |

2200-3300 |

Features

Energy saving

Thanks to the adiabatic compression principle, the total efficiency of oil-free screw blower exceeds 75%, saving more than 20%-35% energy than the Roots blower. The blower is featured with higher discharge pressure and lower pressure pulse.

Low noise

The aerodynamic noise of the screw rotor is very small, and the smooth output eliminates the sudden release of internal air, and the wavy inlet and air outlet minimize airflow fluctuations, so the noise is less than that of traditional blowers.

Intelligent

Intelligent PLC control, remote control and various communication methods are convenient for operation and management

Low cost

The optimized structural design enables the durability of the product with less consumption. Also no special infrastructure is required due to the smooth running and small load of the unit.

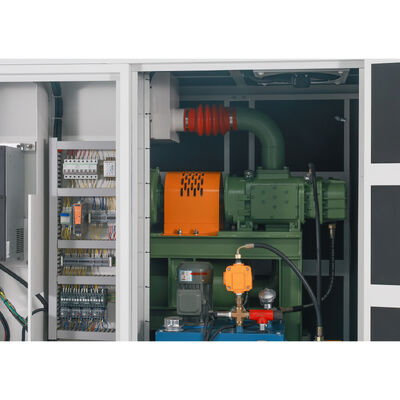

Description of blower parts

|

Shaft screw blower main body

|

high efficiency profile rotor design

● adopt synchronous gear and drive gear of national standard precision grade 5

● Innovative bearing arrangement of screw, fixed radial bearing and thrust bearing adopted to increase the service life

● oil and gas separation between compression chamber and lubricating chamber realized by

Labyrinth seal + carbon ring seal, ensuring the discharge of pure air.

|

|

|

Permanent magnet motor

|

Magnetic properties, no external energy is required to maintain its magnetic field

● High efficiency and energy saving, the average efficiency of 75%- 80% can be achieved in the speed range of 1500-6000r/min.

● High accuracy in voltage regulation can prolong the battery’s service life.

● No brushes, no collector rings, and no sparks generated during operation, so there is no wireless interference,

which greatly improves the operation performance.

|

|

| Oil lubrication system |

More reliable forced circulation lubrication cooling system separately designed

● advanced oil circuit system composed of oil pump, oil cooling and oil filter

● low oil temperature enables longer service life of bearings and gears

|

|

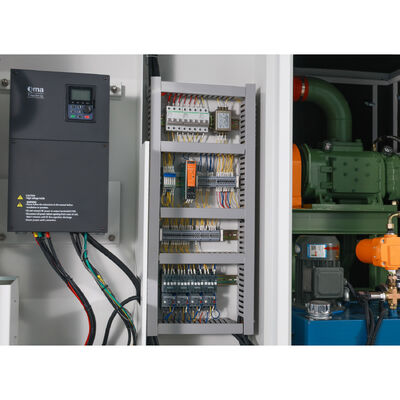

| Operation control system |

Integrated station monitoring instrument, signal control module, inverter, touch screen, etc., no additional installation required

● the selection of driving components is optimized, and parameter settings can accurately achieve higher efficiency

● Complete automatic control and protection functions, and realize online control and remote control at the same time

● A variety of operating modes, enabling users to adjust the operation to be more power-saving mode

according to the changes in working conditions

|

|

Supply Scope

| Items |

Description |

Unit |

Qty. |

Remarks |

| 1 |

Blower main body |

set |

1 |

|

| 2 |

Motor |

set |

1 |

VFD |

| 3 |

Cooling fan |

set |

1 |

|

| 4 |

Heat Exchanger |

set |

1 |

|

| 5 |

Air filter |

set |

1 |

|

| 6 |

Oil filter |

set |

1 |

|

| 7 |

Pressure valve |

set |

1 |

|

| 8 |

Oil pump |

set |

1 |

|

| 9 |

Connection pipe |

pcs |

1 |

|

| 10 |

Contactor |

set |

1 |

Siemens or Schneider |

| 11 |

Inverter |

set |

1 |

Taiwan QMA |

| 12 |

Enclosure |

set |

1 |

|

| 13 |

Check valve |

set |

1 |

|

| 14 |

Stainless steel expansion joint |

set |

1 |

|

| 15 |

Relief valve |

set |

1 |

|

About Us

①In 1994,Yixing Pengde Machinery Co.,Ltd. ( a Sino-Japanese joint Venture) was born,and relocated in the Industrial Park for Environmental SCI and TECH. The following year with company name changed to B-Tohin Machine (Jiangsu)Co.,Ltd.

②Localization of HC blower in 1996.

③In 1999,established a joint venture named Tohin Machine Co.,Ltd. with TUTHILL Pneumatics Group (United States).

④Localization and mass sales of BK blower in 2000.

⑤In 2004,HC Blower and BK Blower got the honor of “new high-tech product”,and the company was rated as a high-tech enterprise. In the same year,the company passed ISO9001 certification,purchased more than 30000 square meters for new plant and donated 500000 yuan to build the B-Tohin Qinghu Hope Middle School.

⑥In 2009,the single-stage high-speed blower was successfully launched, and BK was rated as famous trademark of Wuxi City and famous trademark of Jiangsu Province.The torch program project of Jiangsu Province and a number of patents were achieved ,also the company’s together-with-heart idea: attentively,sincerely,confidently was put forward.

⑦The company’s BK brand was rated as “China Well-known Trademark” in 2013.

⑧In 2014,the company was identified as “Jiangsu Aerodynamic Research Center” by the Science &Technology Department of Jiangsu Province,and got the ISO14001 certificate.At the same time,Office Automation was put into use successfully.

⑨In 2015,the company introduced a whole blower performance test system.Successfully bid for the 2600 square meters industrial assets in Yixing economic development zone and established Wuxi B-Tohin Blower Technology Co.,Ltd.

⑩In 2016, Sino-Korean joint venture Wuxi B-Tohin & Ace Blower Science and Technology Co.,Ltd. was established. In the same year,air foil centrifugal blower was successfully introduced,and Tohin Vietnam Industry was founded.

⑪In 2017,the company turned on the Internet of things intelligent ,the balance tester of Air Bearing Turbo Centrifugal blower was successfully put into use .The Science and Technology Association of B-Tohin was founded.

⑫In 2018, B-Tohin magnetic suspension centrifugal blower,stainless steel blower and other new products were successfully launched.

⑬In2019,Adopted the ERP platform management in the whole company and passed the assessment of “Informational and Industrialize Integration” in 2019.

⑭B-Tohin screw blower was put on market successfully in 2021.

⑮Launched contract energy management and new type product lease sales in 2022.With a new area of 75000 square meters acquired, the project of design and intelligent manufacturing base of high efficiency blower and office building of B-Tohin started.The new factory building was successfully completed and relocated.

Main machine

يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!  يجب أن تكون رسالتك بين 20-3000 حرف!

يجب أن تكون رسالتك بين 20-3000 حرف! من فضلك تفقد بريدك الالكتروني!

من فضلك تفقد بريدك الالكتروني!